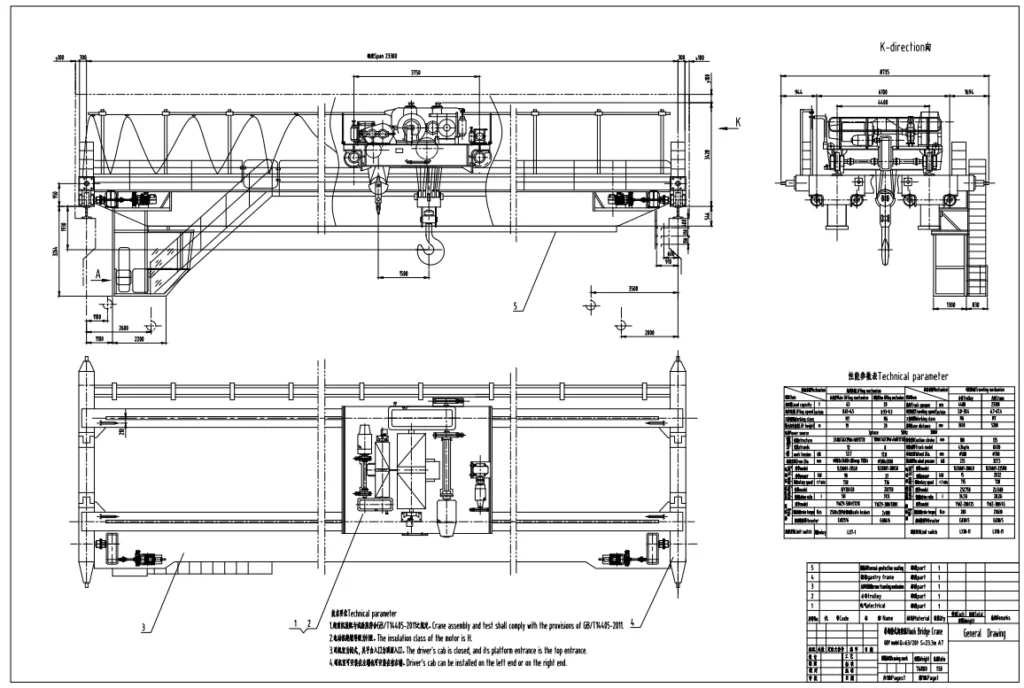

Double Girder Casting Bridge Crane

SWL up to 100 t.

Spans up to 31.5 m.

Temperature: -10-60°C

Working Grade:A7

The Casting Crane is one of the key pieces of equipment in the steelmaking continuous casting process. It is primarily used for loading and transferring molten iron from the converter to the ladle, and for lifting steel from the refining furnace to the ladle or transferring steel to the continuous casting turnaround ladle platform.

The overall structure of the casting crane can be classified into various forms, including: double-girder double-track, four-girder four-track, and four-girder six-track configurations. The double-girder double-track and four-girder four-track forms are generally used for medium to large-tonnage casting cranes, while the four-girder six-track dual-trolley form is typically used for extra-large tonnage casting cranes.

Discription

High Temperature Resistance: Special heat-reflective coatings and thermal barriers protect structural components in environments up to 65°C ambient temperature

Precision Load Control: Dual-motor VFD drives with ±0.5% speed accuracy and anti-sway technology for safe transfer of ladles

Heavy Duty Construction: FEM 3m class design for service life exceeding 500,000 load cycles at 125% rated capacity

Why Choose an Double Girder Casting Bridge Crane?

• Proven Reliability: Over 200 installations in steel mills worldwide

• Low Maintenance: High-temperature lubricants and sealed-for-life bearings

• Smart Features: Optional IoT connectivity for predictive maintenance