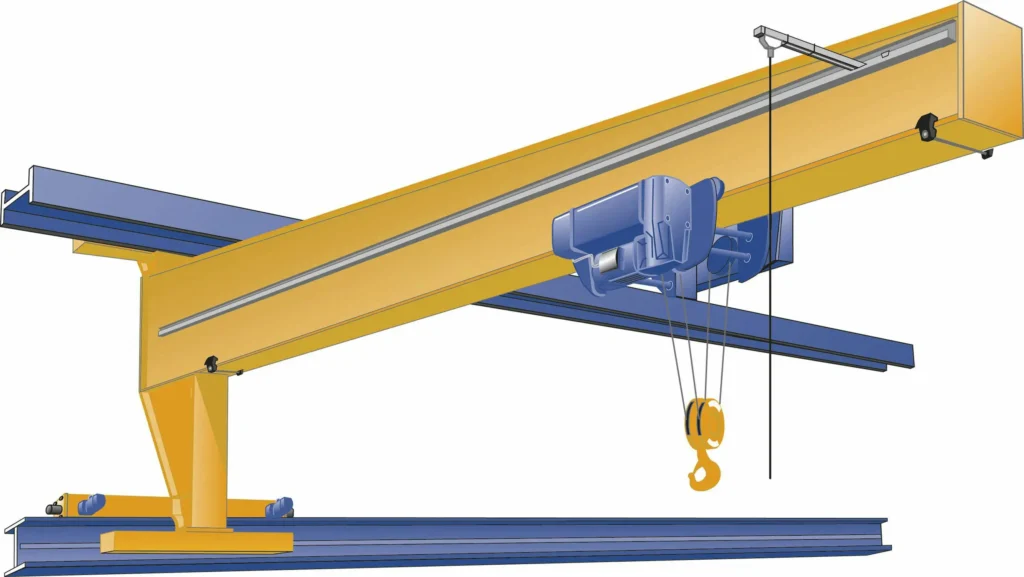

Wall Travelling Jib Cranes

Capacity: up to 5 ton

Arm length: up to 10 m

Lifting height:up to 20m

Work duty: M3-M5

Raged voltage: 220V~690V, 50-60Hz, 3ph AC

Crane control mode: Floor control / Remote control

Typical Applications:

Automotive Plants – Moving engines or components along assembly lines.

Warehouses – Loading/unloading goods in narrow storage aisles.

Shipbuilding – Handling tools or parts along dry dock walls.

Discription

A Wall Travelling Jib Crane is an advanced material handling system that combines the compact design of a wall-mounted jib crane with the extended coverage of a traveling mechanism. Mounted on a runway track attached to a building’s structural wall or columns, this crane features a rotating boom (180°–360°) and a trolley-hoist system that moves horizontally along the track. With load capacities ranging from 0.5 to 10 tons and spans up to 12 meters, it provides unparalleled flexibility for precision lifting in space-constrained industrial environments.

Why Choose an Wall Travelling Jib Cranes?

● Extended Coverage & Flexibility

Horizontal travel along the wall expands the work area significantly compared to fixed jib cranes.

Ideal for long production lines, assembly stations, or warehouse loading zones.

● Space Optimization

No floor columns or supports, maximizing usable floor space for equipment and personnel.

Perfect for facilities with narrow aisles or high-traffic layouts.

● Precision & Efficiency

Smooth electric travel (variable speed options available) ensures accurate load positioning.

Reduces manual handling and speeds up repetitive tasks like part transfers.

● Cost-Effective Solution

Lower installation costs than overhead cranes—utilizes existing wall structures.

Modular design allows customization for specific workflow needs.

● Safety & Ergonomics

Anti-collision sensors and load limiters prevent accidents in busy areas.